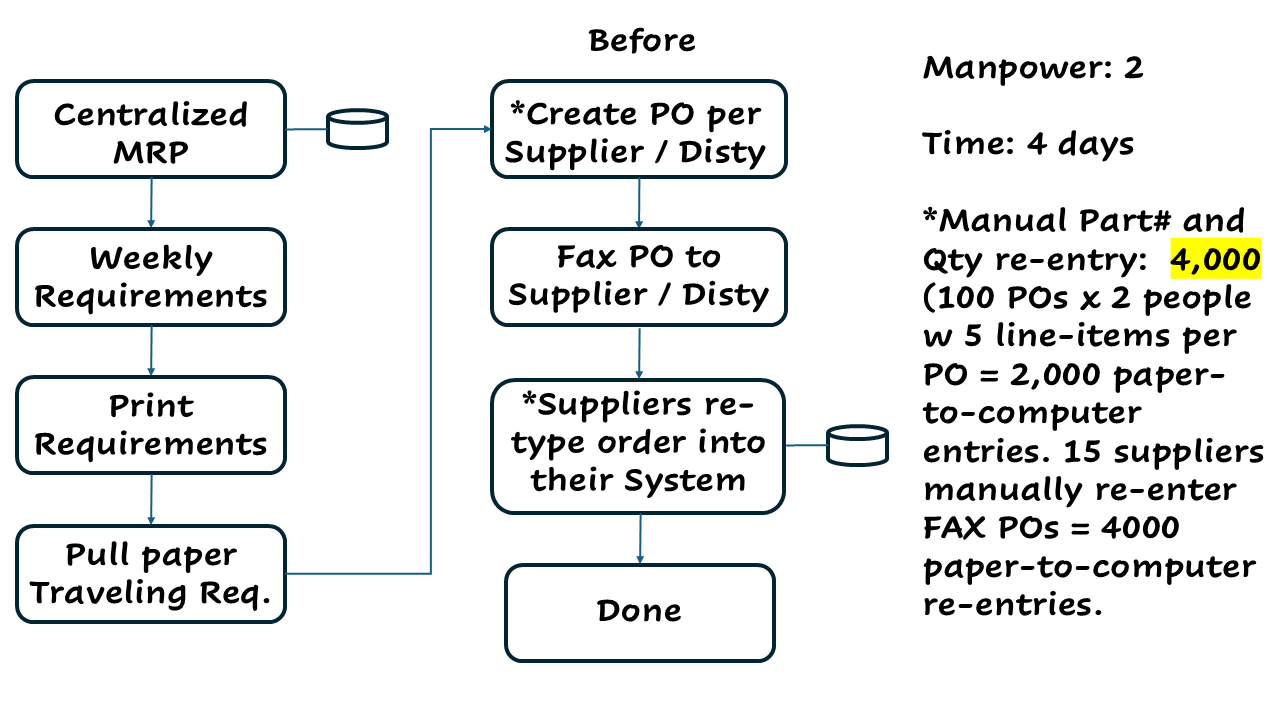

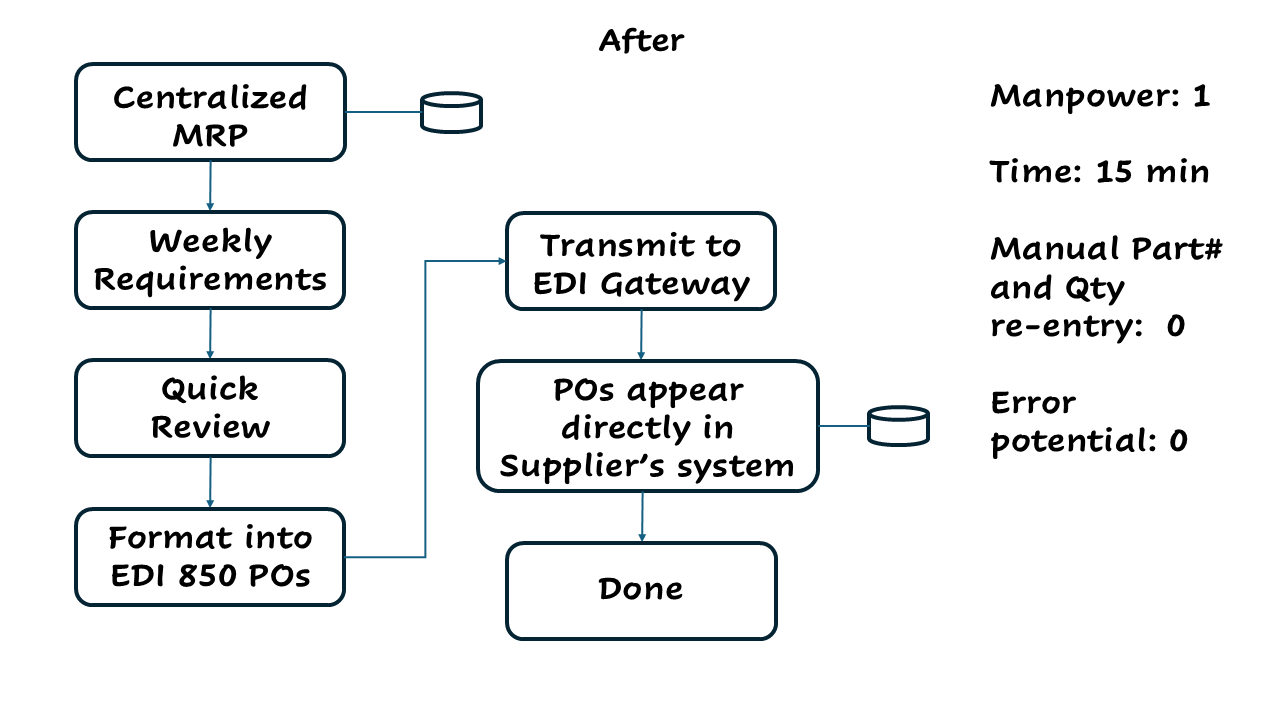

Remote manufacturing plant with small purchasing group reviewing weekly MRP requirements, manually creating multiple purchase orders for each supplier and distributor, faxing, each supplier manually re-entering each line item.

The existing process involved:

- Print weekly material requirements from central MRP System

- Organize by supplier and distributor

- Create Purchase Orders for each supplier by typing in full part number, quantity, date needed, etc.

- Fax Purchase Orders to suppliers and distributors

- Await confirmation via phone or FAX

- Took customer 2 people 4 days per week to complete

- Each supplier had to manually re-enter order from FAX paper to their computer system

- Many opportunities for errors. Any single error would halt production.

Pain Point: Inefficient paper-to-computer re-entry for customer and suppliers. One wrong or missing part number would shut the production line down. Happened frequently.